What is Project PPE?

Project PPE is the engineering and development effort from my company BaselineDesign to create affordable open source medical PPE designs that can be made quickly. Many of the designs have been developed while working directly with medical professionals and hospitals.

*This information and design files are provided without warranty, and without promise of their efficacy*

BaselineDesign is currently owned and operated by myself. I have two products gearing up for release on Kickstarter but have completely redirected my efforts to fighting this pandemic through the founding of MakerForce. MakerForce's focus is creating and delivering PPE to high risk personnel as quickly as possible.

TLDR:

In tandem with my research and development of these OpenSource designs, I also volunteer full-time as founder, and overall manager of MakerForce.

Makerforce is committed to providing the most possible emergency response aid during this covid-19 crisis and I'm going to do everything I can to further that mission (even at the cost of my health and finances). If you're financially able, please consider supporting my work

through a donation at the link below. Your support would allow me to keep fighting this pandemic by prioritizing my research/development of PPE technology, and my activism through Makerforce.

DONATE

Now For Sale!

After receiving hundreds of requests to purchase premade BaselineDesign Masks I've decided to offer complete kits for sale on my store! These masks are made using the same meticulous process followed when manufacturing for healthcare workers, ensuring you receive the highest quality and safest product possible!

Don't worry! The design is still 100% opensource and I am continuing to make masks for medical and essential workers with MakerForce.

The BaselineDesign Mask

Features

| Autoclave Clean | |

| Chemical Resistant | |

| Near Perfect Seal | |

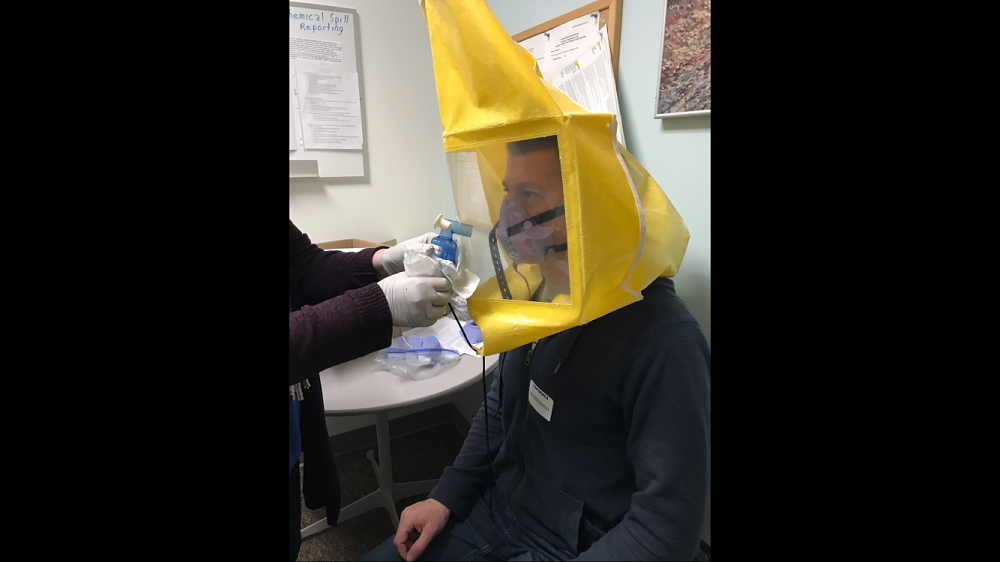

| Passes Medical Fit Test | |

| Currently Undergoing Medical Trials | |

| Fogs Glasses | |

| Infinitely Reusable | |

| Specialty Tools Needed | |

| Cost To Make | $5 |

| Time to Make | 30min (Per Mold) |

| Filter Material | Any |

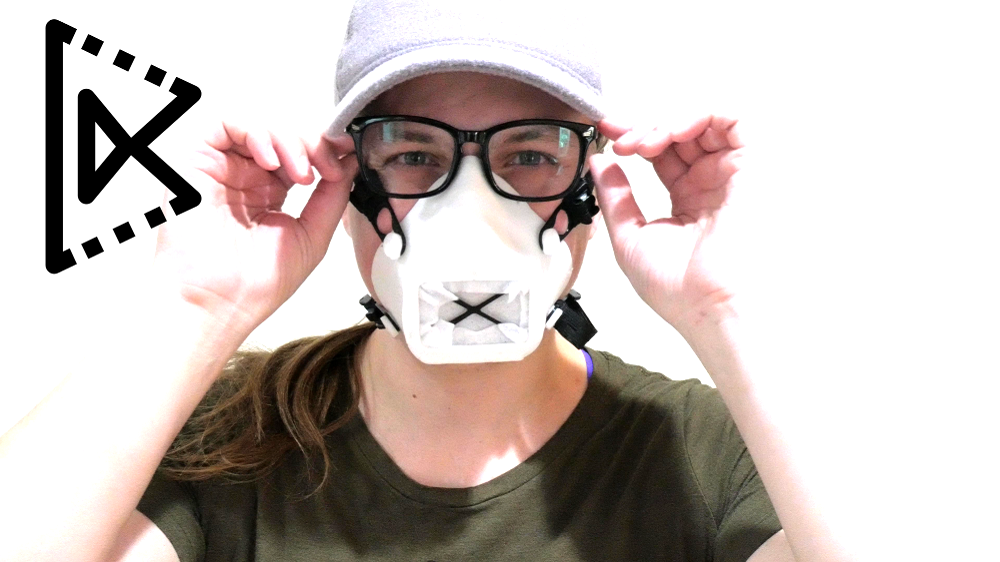

What Is It?

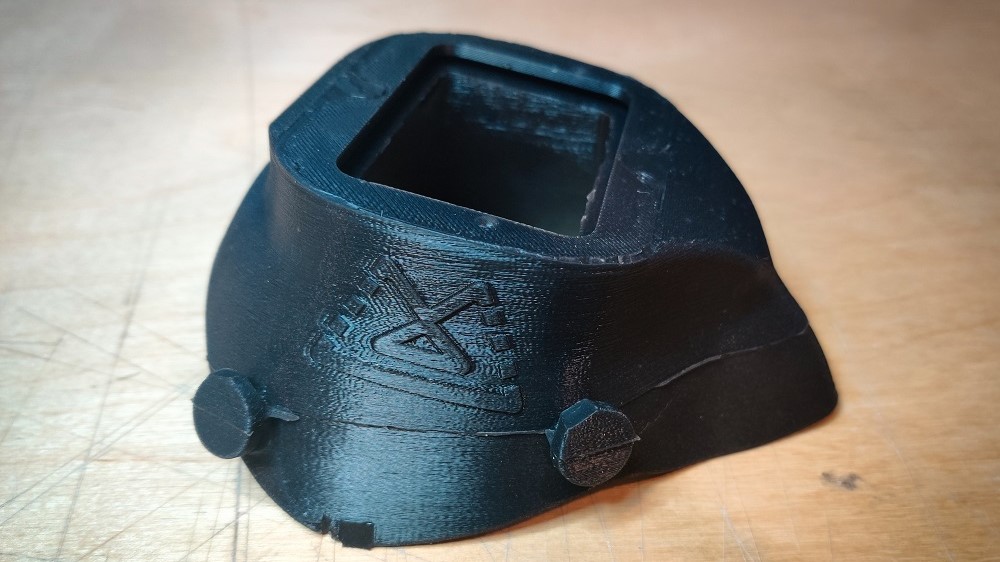

The BaselineDesign Mask was developed to solve the many design flaws of a 3D printed mask while

remaining just as easy and accessible to make. The design uses readily available two-part silicone

poured into a simple 3D printed mold, that's it!

The design is being tested by two medical teams and so far the feedback has been very positive.

Both noted that it's extremely comfortable (even more so than the standard N95) and has passed all fit tests since the Version 4 update

I recognize that the Idea of working with silicone can be quite daunting to someone who has never worked

with it, I assure you it's incredibly easy to use! This project was my first time using liquid silicone and I learned a lot through the process. I tried to include anything important I learned into the instructions but for the most part it should be fairly straight forward.

Version 4 Improvements

V4 introduces a lot of changes that make the mask much more effective while also making the mold much easier to use.

-

Major Improvements Include:

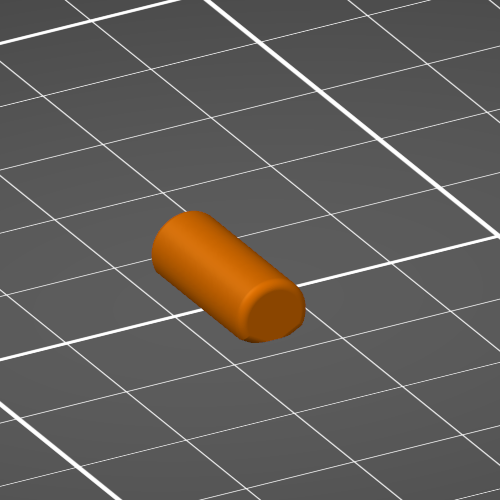

- Addition of a metal nose bridge pocket that significantly improves the masks' seal and broadens the number of people it will fit.

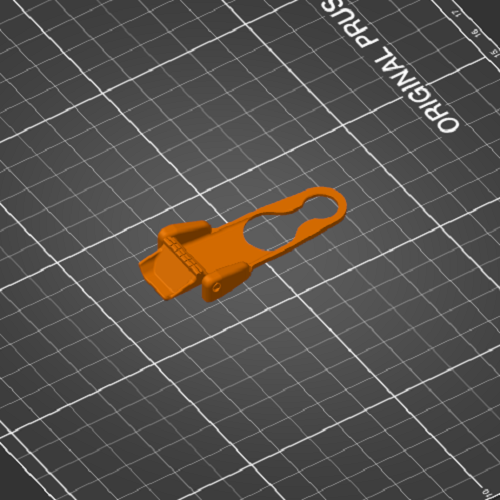

- Button Hole elastic will now longer slip off the mask buttons thanks to the addition of 3D printed buckles! These buckles should also allow for a much broader range of elastic to be used.

-

Minor Known Issues:

- There is a lack of a scientifically tested and NIOSH approved filter material. Some alternatives have public test data but have yet to be tested in a peer reviewed setting against an N95

- Some trial participants noted a slight nose pain after wearing the mask for periods in excess of 6 hours

- Extended use can cause small moisture build up in the mask from users' respiration, this doesn't appear to affect filtering ability but may cause skin irritation if worn for extreme durations

Medical Advisors

The following have been a huge help in the design process of the BaselineDesign Mask. They provide invaluable insight into mask performance requirements and have helped spearhead proper medical trials.

Sean Stone MD, FACEP

Emergency Medicine Specialist and EMS Medical Director at Providence Willamette Falls Medical Center

Lakshmi Mudambi, MD

Assistant Professor of Medicine, Oregon Health & Science University

Director of Interventional Pulmonology at the Portland VA Health Care System

Making a BaselineDesign Mask:

(Clickable Directory)

- Bill of Materials

- 3D Printed Parts

- Using The Mold

- Mask-End User Manual

- More Info

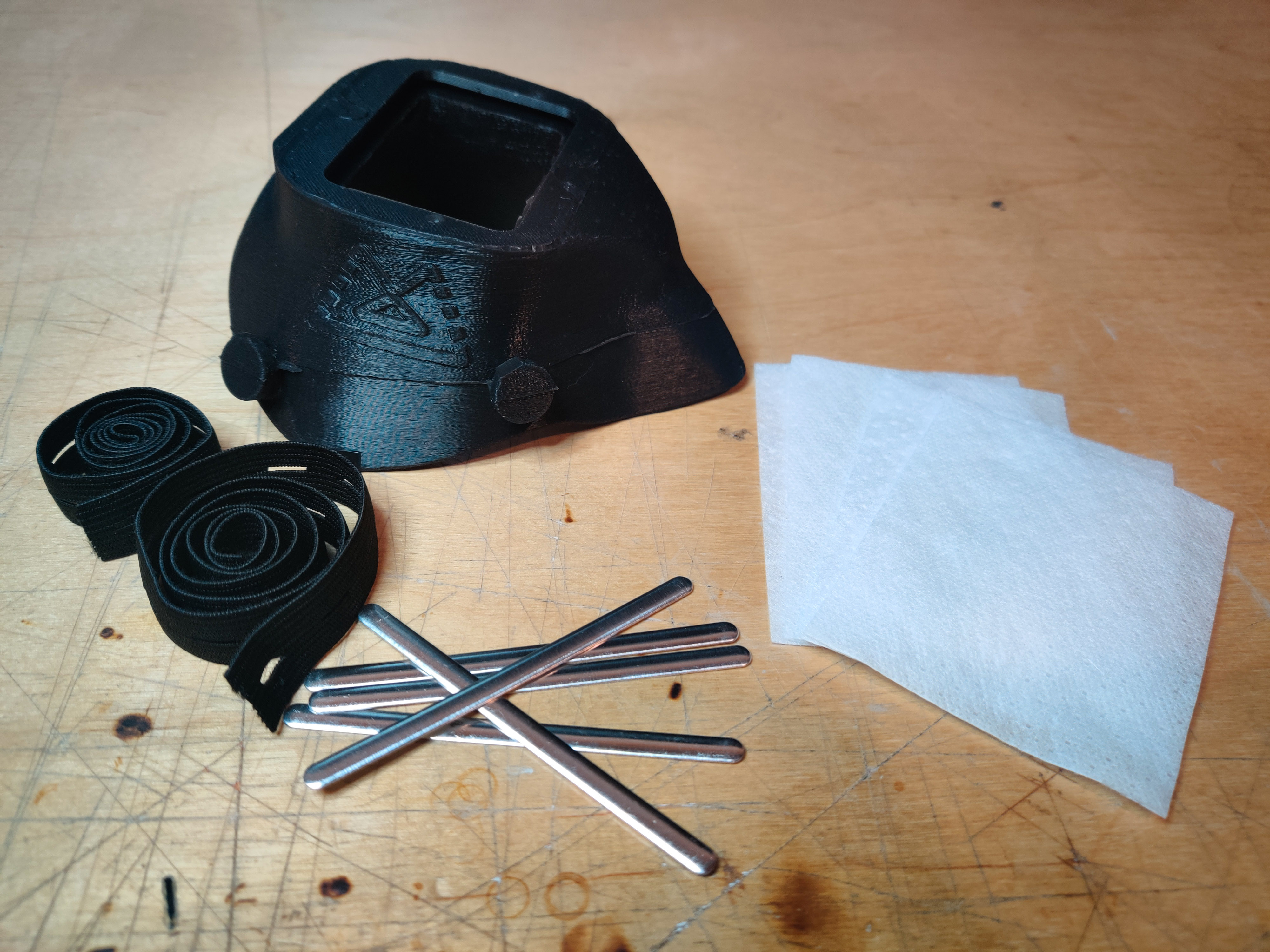

Bill of Materials:

This list is all the materials you'll need to make a single Mask

| Material | QTY | Notes | Vendor Link |

|---|---|---|---|

| Two-Part Silicone | 160ml | Mold Star 20T (Check out my notes for alternative 2-part silicones) | Amazon |

| PLA Filament | 500g | I have only tested PLA and have accounted for it's shrinkage. I'm sure a different plastic would work but can't guarantee the mold halves will fit together. | Amazon |

| Small Mixing Container | 1 | I used the linked plastic cup, it's volume markings make measuring the correct mixture really easy. | Amazon |

| Mixing Sticks | 3 | Most anything will work as a mixing stick just make sure it is properly cleaned. A handful of materials will inhibit the silicone cure, if you're not sure try a small mixture to test. | Amazon |

| Button Hole Elastic | 32in | The new elastic buckle design allows for any 5/8" elastic to be used. Buttonhole elastic is preferred because it allows for the buckle's safety mechanism to be used. | BaselineDesign Shop |

| Filter Material | 3.5"x4" | This mask design will work with any filter material. I use Filti filter material due to their availability and performance in independent tests. Similar to the early 3D printed masks, an N95 (preferably that failed fit testing) can be cutup and used as the filter square. | BaselineDesign Shop |

| Nose Bridge Wire | 1-4 | All testing has been done with 85mmx5mmx.7mm adhesive backed aluminum strip. Alternative nose bridge wire may work but see my notes on what materials to avoid before looking elsewhere. | BaselineDesign Shop |

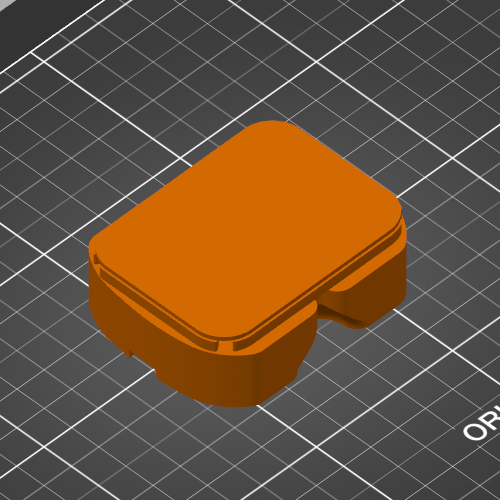

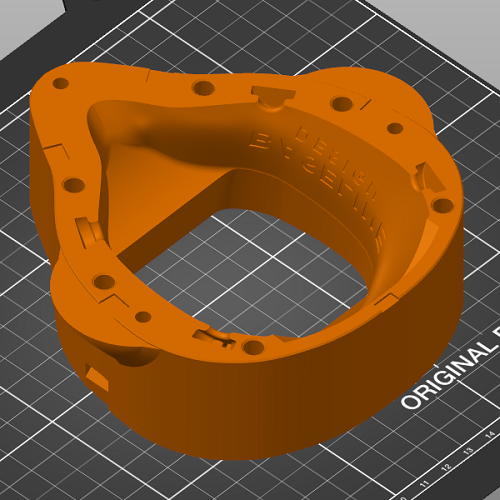

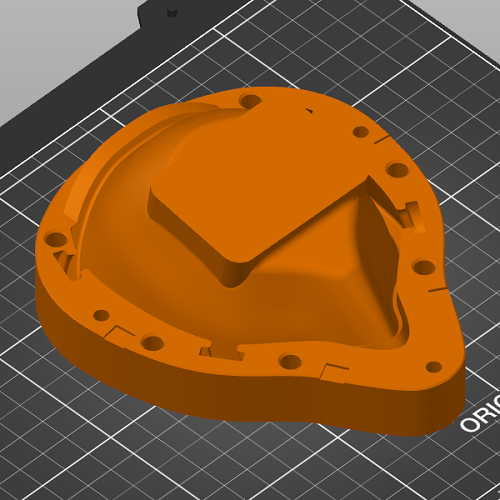

3D Printed Parts

Print List:

Part Name:

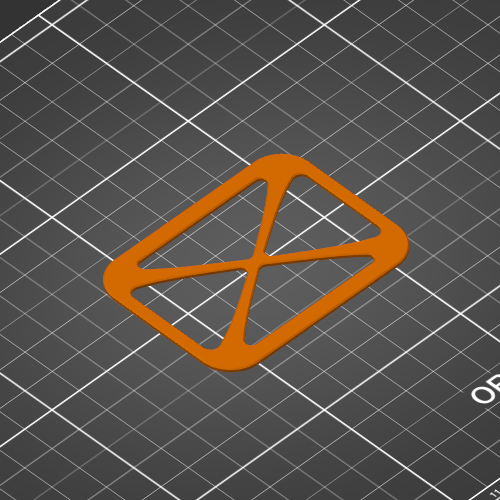

BaselineDesign Mask V4-

External Cavity V2

Print Settings:

Part Name:

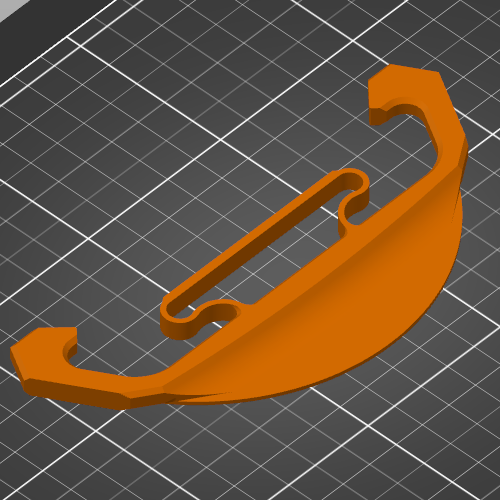

BaselineDesign Mask V4-

Internal Cavity V2

Print Settings:

Part Name:

BaselineDesign Mask V4-

Filter Retainer V2

Print Settings:

Part Name:

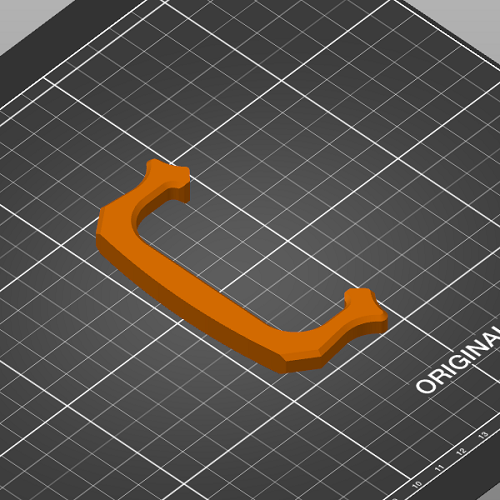

BaselineDesign Mask V4-

Clamp Exterior V2

Print Settings:

Part Name:

BaselineDesign Mask V4-

Clamp Insert V2

Print Settings:

Part Name:

BaselineDesign Mask V4-

Elastic Buckle .6in V2

Print Settings:

Mask Video User Manual:

Cleaning Notes:

The most surefire and safest way to clean a BaselineDesign Mask is to allow the mask to soak over night in soapy water (preferably dish soap) and then place the mask out to air dry. This will ensure thorough cleaning and does not use any harsh chemicals.

More Mask Info:

Silicone Notes:

What to look for: From my testing and research an ideal silicone for mask making has the following specs: Skin safe certified (or at the very least platinum cure), low cure time (for small batches), a pot life no less than 6 minutes, die b tear strength > 90 pli, and doesn't require vacuum degassing. Anything with those specs should work but I've added some notes on what I've tried as a starting point.

Interesting Findings:

- After doing some digging I found a list of all smooth-on products that have been independently tested to be skin safe. Most of the silicones on this list should work for the mask, although I'm weary of the Ecoflex line because it might not be stiff enough to securely hold a filter. If you've found a different supplier that advertises skin safe silicone let me know! I'd love to add it to these notes.

- One really interesting finding was that temperature can have a significant effect on the pot life and cure time of plat-cure silicone. By cooling you can draw out it's cure time, and by heating the mixture you can significantly reduce the cure time. I did some testing with Mold Star 20T and was able to get the pot life from just 6min to well over 25mins by chilling it in the fridge before mixing. Then I printed some molds out of ASA and was able to cure a mask in just 10 mins in the oven (although the ASA molds came out really porous and created unusable masks, it could have just been my print settings though).

- I also tracked down this incredible website on how to clean medical grade silicone which is worth a look

Smooth-On Mold Star 20T: This has an incredible 30min cure time and a very anxiety inducing 6min pot life. The masks made with this appear to be more resilient that the OOMOO but again, more testing is needed. When cured this silicone is transparent and smooth-on sells dyes that can be added to make whatever color you want. Because it is a Platinum cure silicone it's noticeably more expensive that the tin cure OOMOO. A sample kit (the minimum amount you can buy) is around 40 dollars and makes at least masks.

Pros: Platinum cure, higher tear strength, short cure time, common (fast shipping), clear when

cured

Cons: clear when mixing, low pot life, price

Smooth-On Dragon Skin 20: so far this is my favorite for ease of use, as long as you aren't in a hurry. It's 25 minute pot life is far more forgiving and gives you plenty of time to mix and work out air bubbles. It's also semi-transparent like 20T so with a little pigment you can make it whatever color you want.

Pros: Platinum cure, higher tear strength, clear when cured, long pot life for lower stress pours.

Cons: clear when mixing, highest price

Smooth-On OOMOO 30: *This silicone is not advertised as skin safe by Smooth-On and I no longer recommend using it.

For initial testing I used OOMOO 30 with no issues besides it's 6hr cure time. long pot life make's it really usable for people new to silicone and part A & B being different colors

makes it easy to tell when both are thoroughly mixed. Although I did have issues with the buttons that

hold the elastic tearing out when I used this silicone. Under normal use it should be fine but further

testing is needed.

Pros: great for beginners (mix by volume, A & B different colors, long pot life),affordable,

common (fast shipping)

Cons: tin cure, low tear strength, long cure time, fixed color

Nose Bridge Notes:

What to look for: An ideal nose bridge wire should be made of non-corroding ductile material that has noticeable spring back once bent. Steel and other materials with low resistance to corrosion should be avoided as they will oxidize when subject to the constant cleaning the mask will go through. Keep in mind the masks' silicone requires slightly more force than a normal cloth mask to seal around the nose. I'm pretty sure stainless steel strips would be the best material but I haven't had any luck finding a reliable source of thin stainless steel that won't take significant effort to make into nose wire.

Currently I'm using these adhesive backed aluminum strips that have shown good results in fit testing. One strip by itself wont create a enough sealing force for most people, but thanks to the adhesive you can stack the strips and try different thicknesses. Stacking 3 strips seems to be the ideal thickness for most people but your results may vary.

Media Coverage:

Local college student works to improve protective face masks, creates silicone-based design

KOIN 6

Meaningful Medical Making: Sourcing Designs and Fostering Relationships in a Crisis

Open Source Medical Supplies

“Gamemaster” Partners With Makerforce

RCR News Media

WSU student uses 3D printer to make protective masks

Spokesman Review

COUGKIE CUTTER FOUNDER PRODUCES FACE SHIELDS FOR MEDICAL PERSONNEL

WSU IMPACT

Portland Area 3D Print Makers Form PPE ‘Emergency Response’

OPB

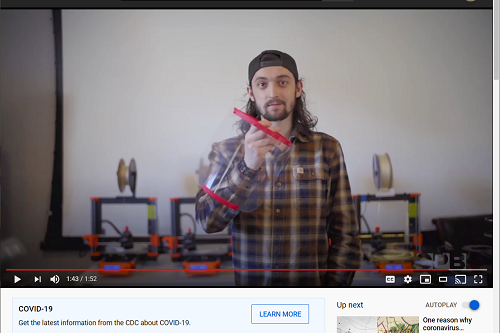

3D Printing PPE For Health Care Workers—Postcards From The Pandemic

OPB - YouTube

Local 3D printing community comes together to print PPE for hospitals

KPTV

Volunteers 3D print medical supplies amid COVID-19 shortages

KOIN 6

Local 3D printers help with medical PPE shortage

KOIN 6

3D printing community steps up to help with PPE shortage

KGW 8

CREATING A POP-UP SUPPLY CHAIN FOR COVID19 PPE

Shashi Jain (MakerForce Co-Founder)

3D Printer Groups Continue Working Round The Clock To Help 2020 PPE Shortage

Forbes

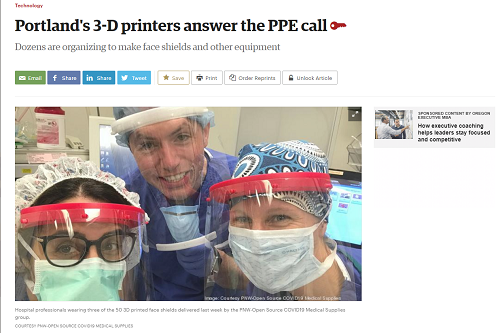

Portland's 3-D printers answer the PPE call

Portland Business Journal

3D Printing and COVID-19, April 19, 2020 Update

3DPRINT.COM

Pacific Faculty, Staff, Students Rise to Meet the Challenges Posed by COVID-19

PSU

Global e-NABLE Chapters Delivering Medical Supplies During COVID-19 Pandemic

EnablingTheFuture.org

Portland grassroots manufacturing heroes equip frontline healthcare heroes with PPE

Silicon Florist

Working Class Heroes: Corona Virus & Class Wars

Isabelle Bartter on Pacifica Radio NYC

Unleashing a Supply Chain Revolution with Shashi Jain

Creative Revolution Podcast S3E4

GEORGIA-BASED PRODUCTION “GAMEMASTER” TO COLLABORATE WITH MAKERFORCE IN ONGOING GAMERS VS. COVID CAMPAIGN

OZ Magazine

Gladstone mentors deliver face shields to local businesses

Clackamas Review